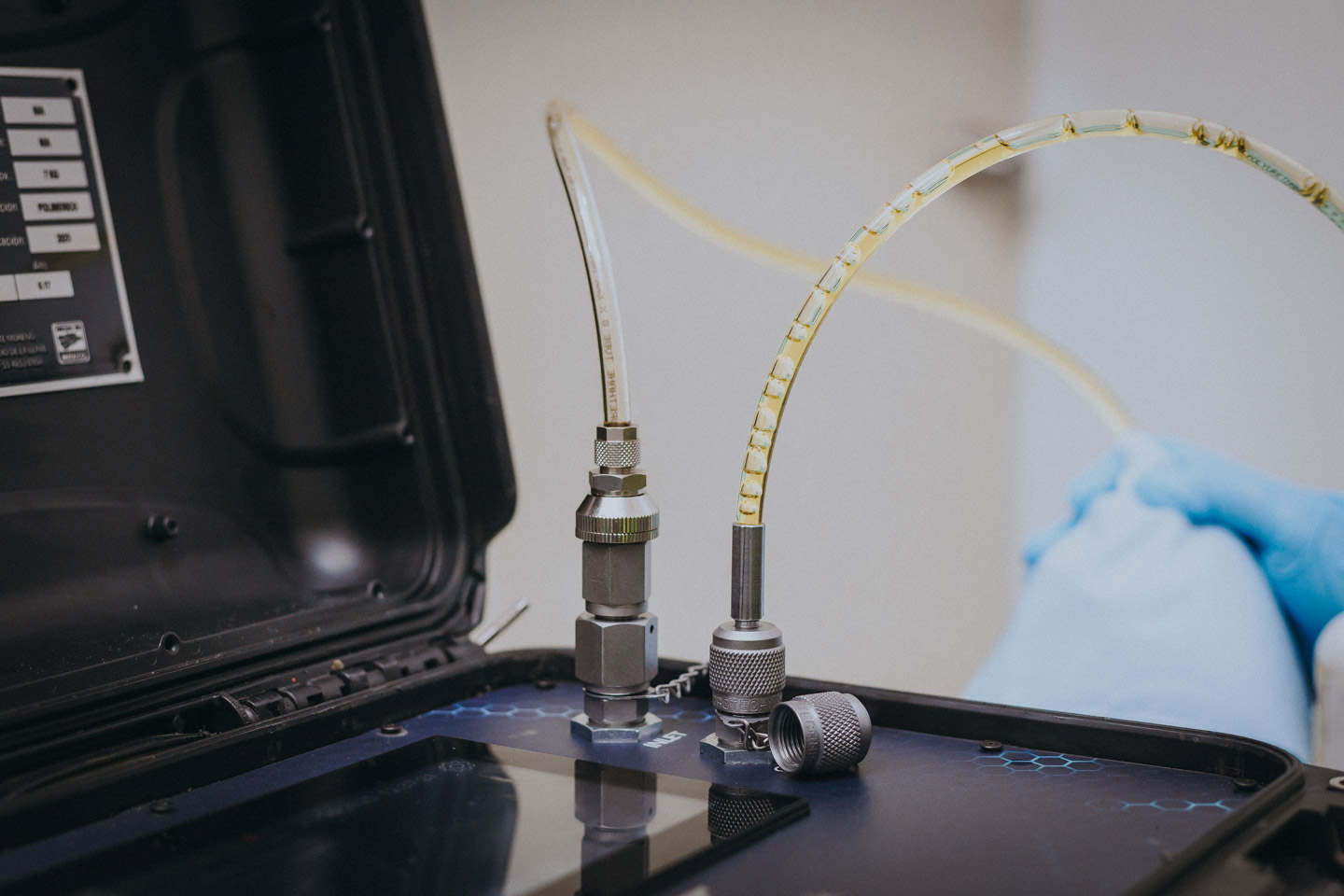

Oil Conditioning

Efficient Lubrication, Productive Equipment

At FLUDEXSA, we understand that lubricant quality is key to the performance of your industrial equipment. That’s why we offer a specialized oil conditioning service, designed to eliminate contaminants, optimize the operation of critical machinery, and reduce premature wear.

This process not only extends the oil’s useful life, but also increases the efficiency of lubrication systems, reduces unscheduled downtime, and represents significant savings in operating and maintenance costs.